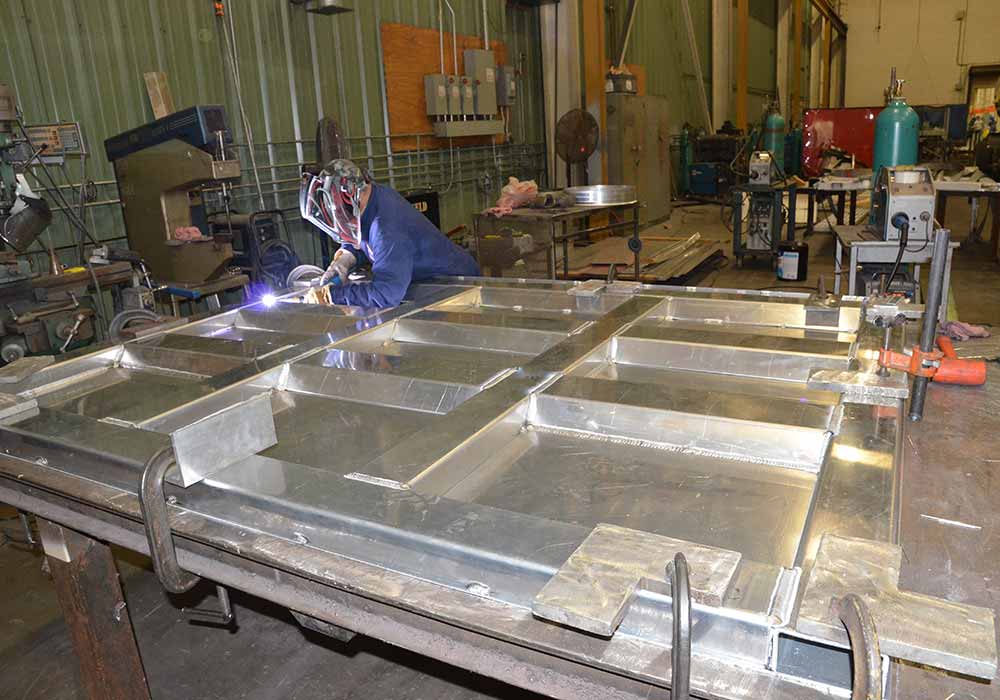

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing fusion, which is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal. In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that is usually stronger than the base material. Pressure may also be used in conjunction with heat, or by itself, to produce a weld. Standard weld methods are GMAW (Gas Metal Arc Welding), GTAW (Gas Tungsten Arc Welding) and Spot Welding.

GMAW

GMAW (Gas Metal Arc Welding) – commonly referred to as MIG welding - is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to melt and join.

GTAW

GTAW (Gas Tungsten Arc Welding) – xommonly referred to as TIG welding - is an arc welding process that uses a non-consumable tungsten electrode to produce the weld.

The weld area is protected from atmospheric contamination by an inert shielding gas (argon or helium), and a filler metal is normally used, though some welds, known as autogenous welds, do not require it.

A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma.

Robotic Welding

Robotic welding is the use of mechanized programmable tools (robots), which completely automate a welding process by both performing the weld and handling the part. Processes such as gas metal arc welding, while often automated, are not necessarily equivalent to robot welding, since a human operator sometimes prepares the materials to be welded. Robot welding is commonly used for resistance spot welding and arc welding in high production applications, such as the automotive industry.

Robot welding is a relatively new application of robotics, even though robots were first introduced into US industry during the 1960s. The use of robots in welding did not take off until the 1980s, when the automotive industry began using robots extensively for spot welding. Since then, both the number of robots used in industry and the number of their applications has grown greatly. In 2005, more than 120,000 robots were in use in North American industry, about half of them for welding.[1] Growth is primarily limited by high equipment costs, and the resulting restriction to high-production applications.

Robot arc welding has begun growing quickly just recently, and already it commands about 20% of industrial robot applications. The major components of arc welding robots are the manipulator or the mechanical unit and the controller, which acts as the robot's "brain". The manipulator is what makes the robot move, and the design of these systems can be categorized into several common types, such as SCARA and cartesian coordinate robot, which use different coordinate systems to direct the arms of the machine.